TECHNOLOGIES

UNDERSTANDING PADDLEBOARD TECHNOLOGIES

We've made great investments in our technologies so we can deliver to you high-end performance paddleboards as well as durable recreational paddleboards at affordable prices.

RIGID COMPOSITE

Rigid Composite boards are a best in class paddleboards made from fiberglass, carbon fiber, or other fiber materials held together by a resin, infused in the fibers, and hardened around a lightweight EPS foam core. Composite boards give you the best performance because you can shape the finest of details into the board, controlling its efficiency through water, flex, weight, and durability.

THERMOFORMED TECHNOLOGY

Thermoformed boards provide maximum durability using our proprietary ACE-TEC and TOUGH-TEC manufacturing process. ACE-TEC uses similar materials as our composite boards but is capped-off with a polymer skin. TOUGH-TEC manufacturing uses durable polyethylene skin over the EPS foam core for maximum durability. These boards are molded for strength and consistency of quality at an affordable price.

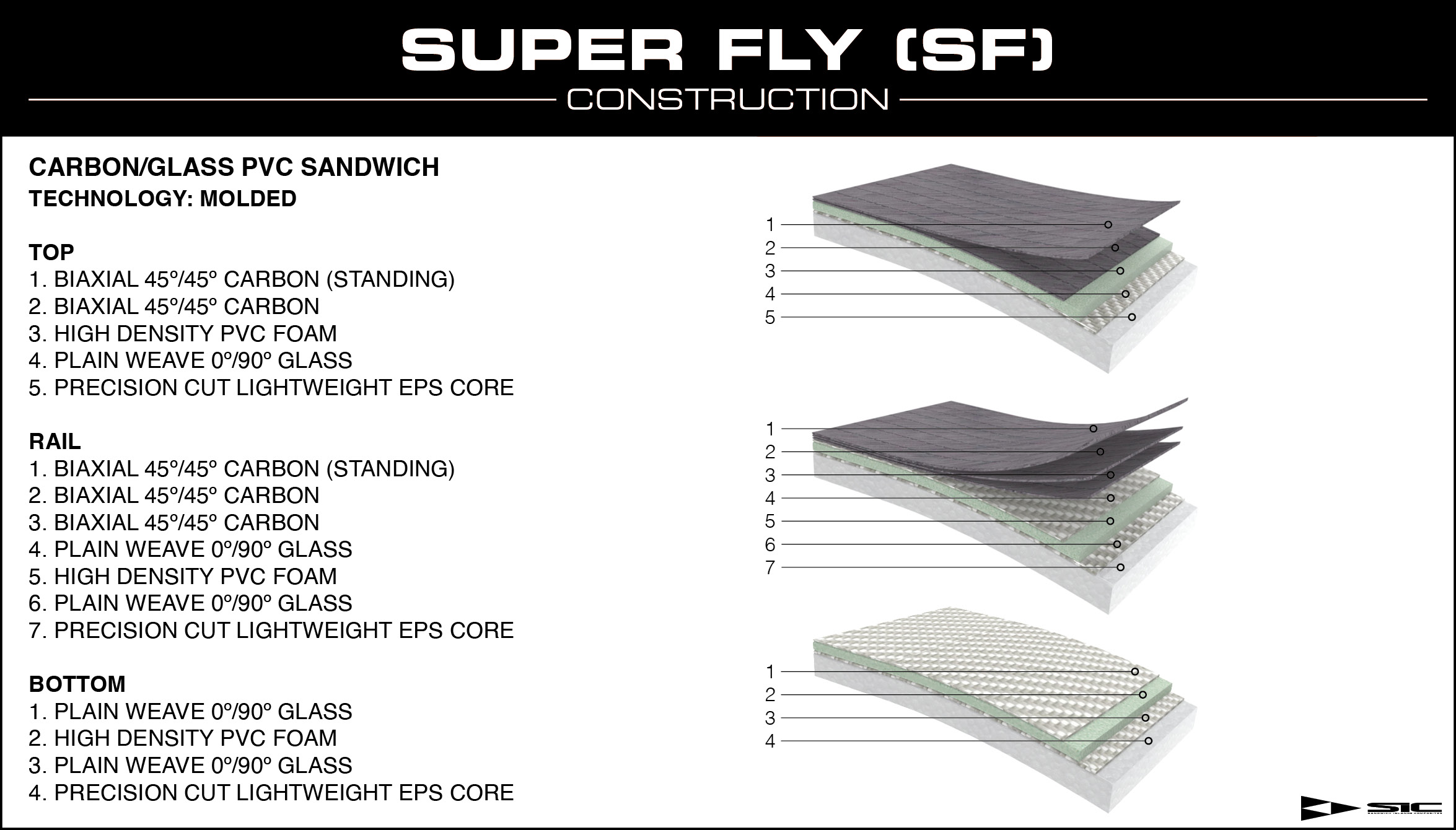

SUPER FLY (SF) is constructed with a lightweight EPS core that is fully wrapped in high-density PVC tip-to-tail and 360 degree around the rail and then sandwiched between fiberglass and carbon fiber for superior stiffness, durability, and performance.

UNLIMITED (UNL) is constructed with a lightweight EPS core that is wrapped in biaxial carbon lapped over the rails doubling the rail and overall strength. The rails, tip, and tail are reinforced with biaxial glass. The standing area is reinforced with high-density PVC for extra stiffness and impact strength.

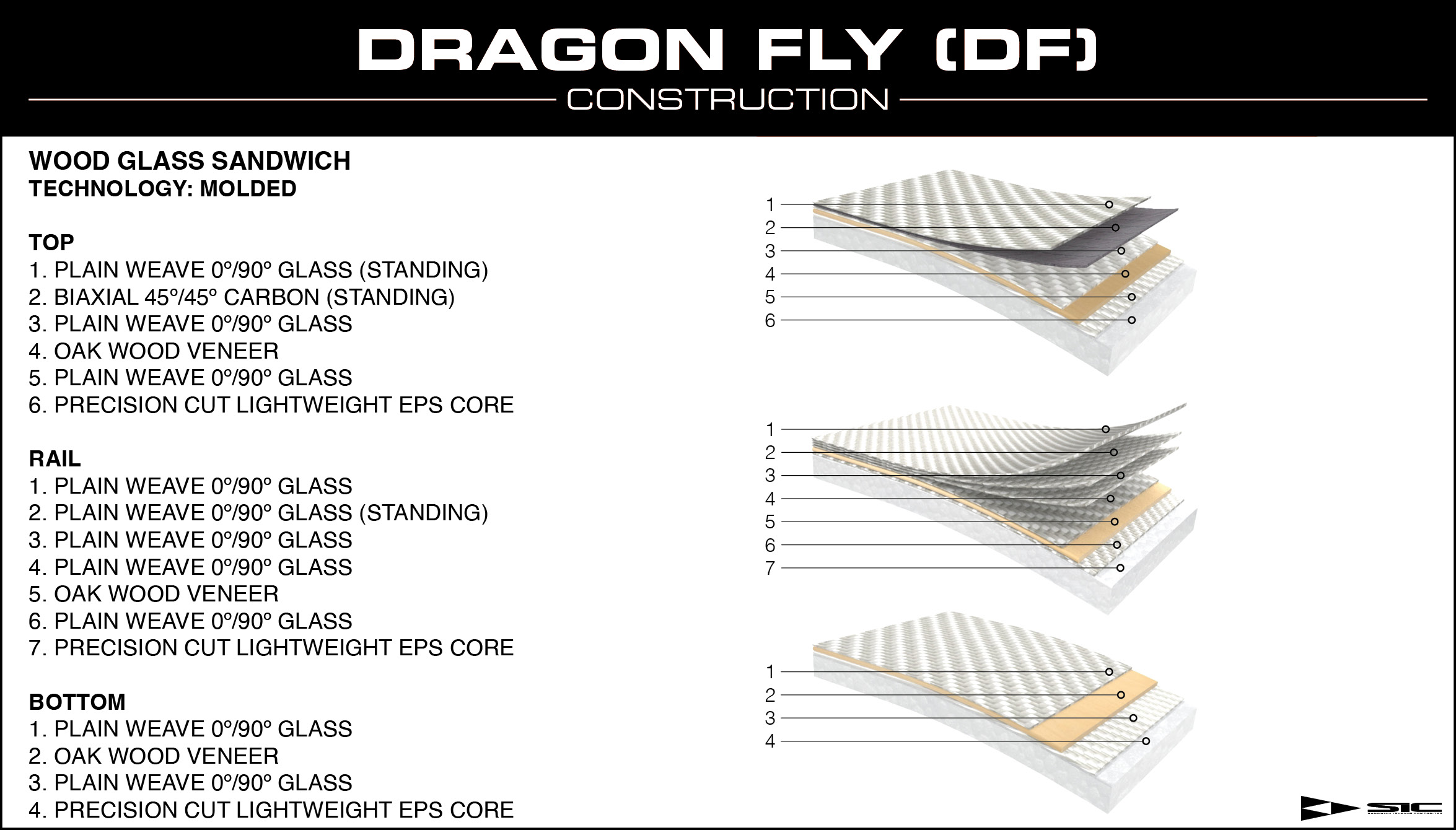

DRAGON FLY (DF) is constructed with a lightweight EPS core that is

sandwiched top and bottom with an oak wood deck and bottom laminate,

which is then wrapped in fiberglass for superior stiffness, durability, and

performance.

GLASS CARBON COMPOSITE + INNEGRA (GCC+) is construction

with a lightweight EPS core, oak wood laminate sandwich top and bottom

and double wrap carbon and fiberglass layup with Innegra™ tip, tail and rail

reinforcement.

GLASS COMPOSITE + INNEGRA (GC+) Is construction with a lightweight EPS core, oak wood laminate sandwich top and bottom and double wrap fiberglass layup with Innegra™️ tip, tail and rail reinforcement.

Both ACE-TEC and TOUGH-TEC utilize thermo-formed skins, watertight EPS cores, and externally molded inserts. The lighter weight ACE-TEC is constructed with a durable polymer outer skin, thermo-formed over a fiberglass-wrapped, stringerless EPS core for a lively and responsive performance.

TOUGH-TEC boards are manufactured in an eco-friendly way with virtually zero waste generated during the production process. The boards can be completely recycled, which is excellent for the environment. These boards are ideal for beginners, schools, clubs, and paddlers with an eco-conscience, and they can take a serious beating.

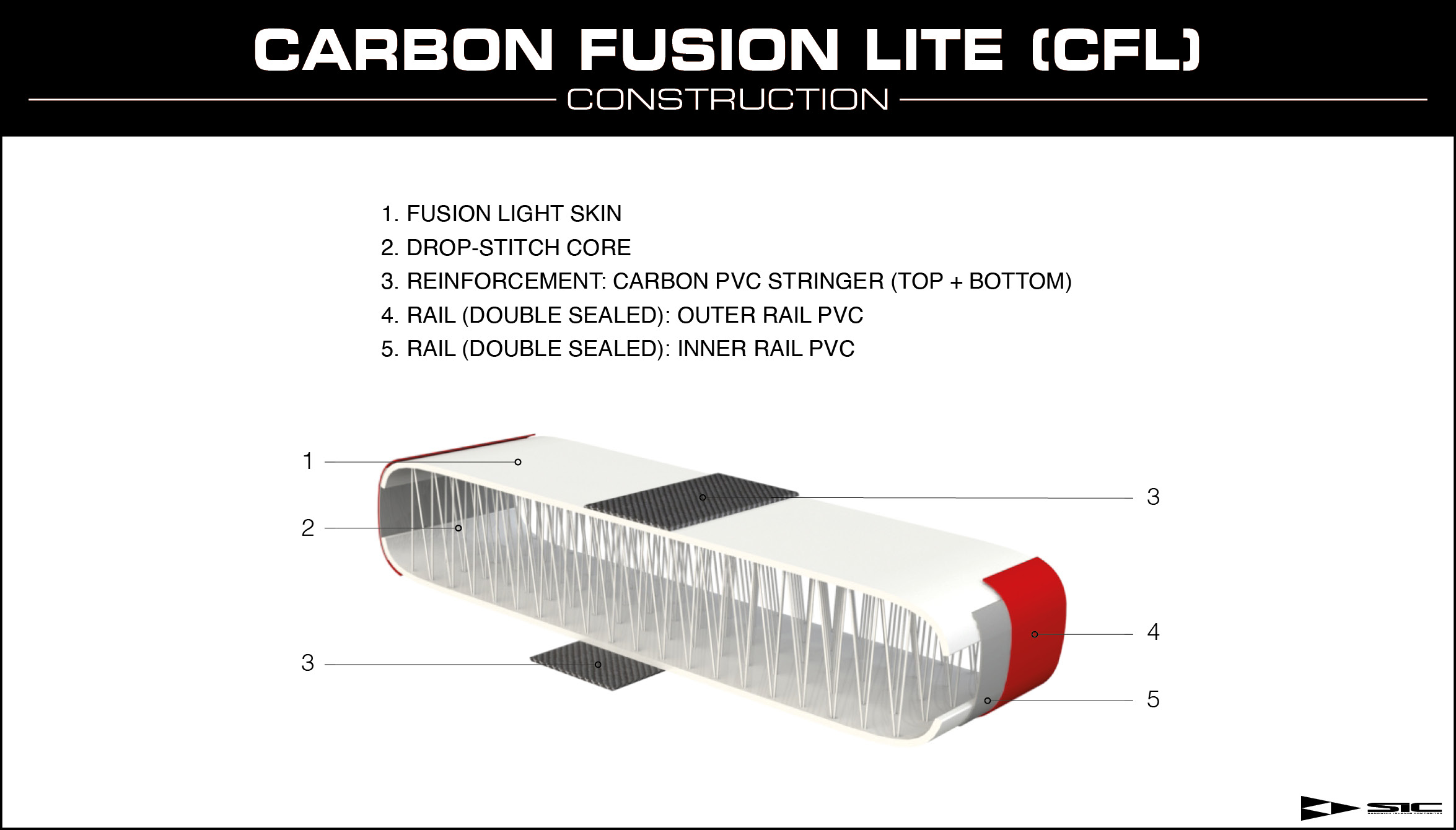

Carbon Fusion Lite (CFL) is the newest and lightest Fusion skin material on the market. This material has a lightweight, low-stretch, high tensile skin, which is heat-fused onto the back of the outer PVC outer skin. When inflated with the compound curves of the rails, this stiffer skin makes this board super stiff at only 15 psi. The carbon fused PVC belt on the top and bottom of the board provides increased longitudinal stiffness for one of the most high-performance paddling inflatables on the market today.

Fusion Skin Technology w / Double Chamber (FSTX2) utilizes Fusion Skin Technology; however, in this design, the board also has a secondary, independent, air bladder system inside the board. The chamber provides a failover should you ever have a problem with one chamber while out on the water. The double chamber system is safer and it makes the board even stiffer than a single chamber board. The internal chamber is pumped first to a maximum of 12 psi while the outer chamber should be pumped to 15 psi.

FUSION SKIN TECHNOLOGY (FST) is the stiffest drop-stitch material you can build an inflatable board with. This material has a low-stretch, high tensile skin, which is heat-fused onto the base fabric. When inflated, this stiffer skin, combinedwith the compound curves of the rails, makes this board superstiff at only 15 psi.

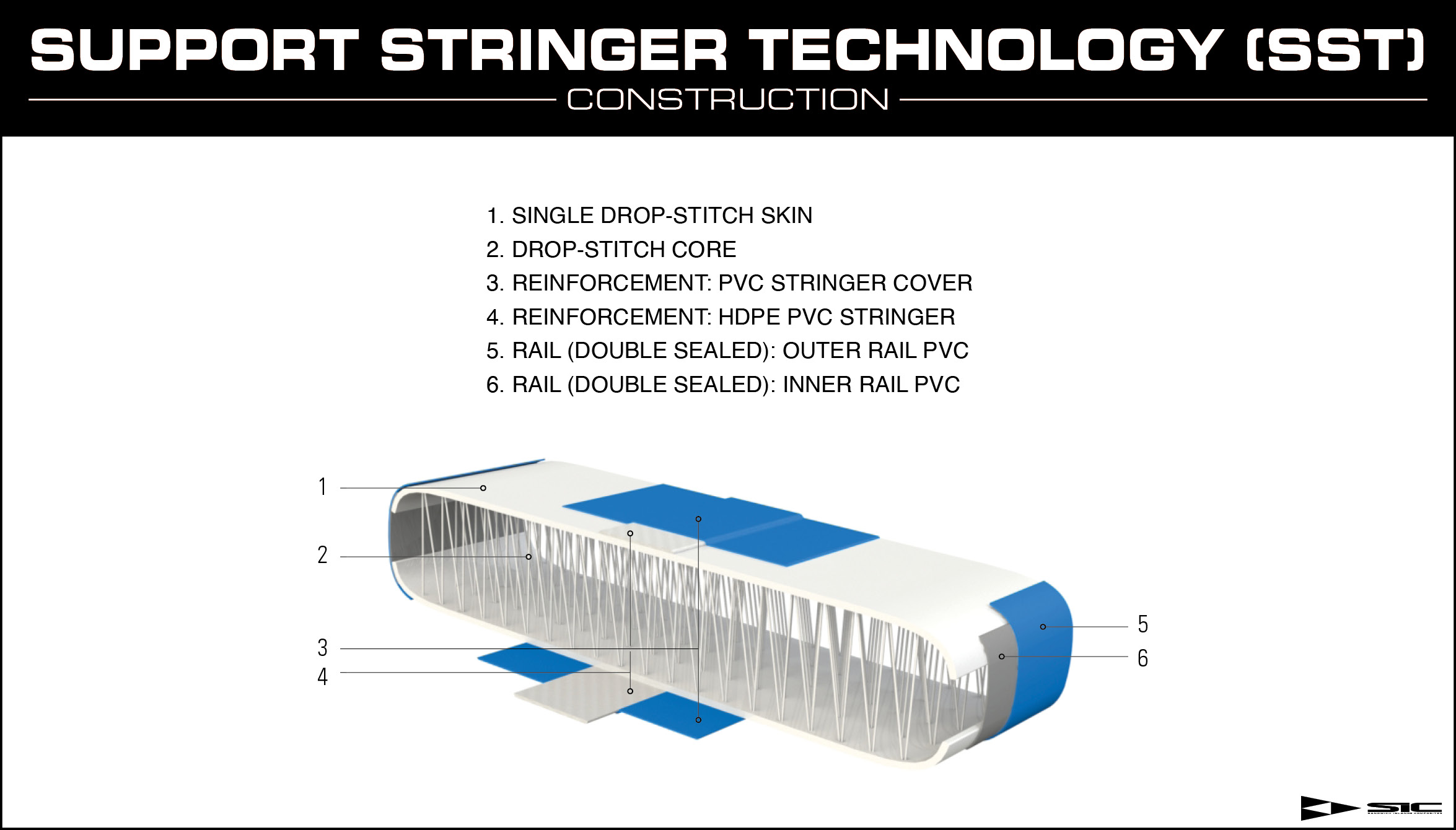

SUPPORT STRINGER TECHNOLOGY (SST) The TAO Series boards are constructed from a single skin Drop Stitch material (DSC) that is lightweight and extremely durable. They also utilize Support Stringer Technology (SST), which is an HDPE stringer, heat fused onto PVC to stiffen the board and lock in the rocker profile.

INFLATABLE PADDLEBOARDS

Inflatable (Air-Glide) boards are compact, lightweight, and ready to go when you are. They roll up into a backpack carrier, complete with a pump, fin, leash, and repair kit. Some come packaged with three pieces of collapsible/adjustable paddle that slides nicely inside your backpack. These boards span the gamut of shape and performance, making a shape and style inflatable for every paddling discipline.